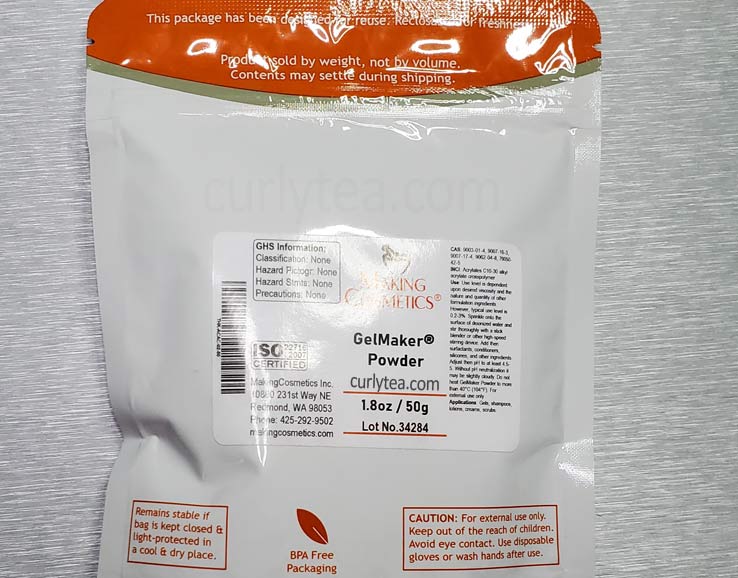

Gelmaker Powder – Acrylates/C10-30 alkyl acrylate crosspolymer

| INCI | Acrylates C10-30 alkyl acrylate crosspolymer |

| WHAT | self-wetting polymer; thickener |

| SOLUBILITY | water |

| USAGE RATE | typical 0.2% – 3% |

| SIMILAR/SAME | carbopol ultrez 20 |

| REQUIREMENTS | adjust pH to at least 5 to realize superior thickening properties |

I didn’t see this coming but the self-wetting Acrylates C10-30 alkyl acrylate crosspolymer, aka GelMaker Powder, has been very nice to work with. It creates super thick gel without feeling heavy, goopy or draggy. It can create a quick-breaking gel.

The Gelmaker Powder is the rapidly dissolving, self-wetting version which doesn’t form globs of fish eyes when added directly into water.

There are various grades/versions of Acrylates C10-30 alkyl acrylate crosspolymer with the exact same INCI name. Be careful when ordering. Look for a designation like “self-wetting” or “rapid”. That’s the grade which mixes easily into water and the grade to which I am referring in this post.

Sign up!

Join the community to get access to all of the formulas and recipes!

Makingcosmetics.com advertises this version as “just like carbopol ultrez 20”. It probably means Lubrizol may be the manufacturer of this version but the supplier can’t advertise it under the “Carbopol Ultrez 20” name because of trademark issues.

According to Lubrizol’s information about “Carbopol Ultrez 20” it “self-wets in minutes, without mixing” (2). Yep.

Like the supplier states, it “requires only minimal agitation” (1). I tested this in the Centella DMAE Serum recipe. I literally added it to the water and manually stirred with a spatula to see how it would dissolve. No clumps. No fisheyes.

To use this polymer with emulsions: Add it to water, let it dissolve (very little to no white showing), stir well, then add your other water-soluble ingredients. THEN adjust the pH to 4.5 or above. THEN, incorporate oil soluble ingredients into the gel. (For surfactants, see the info further down in this post)

What’s great about this polymer is the pH can be adjusted more than once. Let’s say you adjusted the pH to test how thick of a gel it would create. But then you added another ingredient which significantly lowered the pH, causing the batch to turn back into a liquid. You only need to adjust the pH back to within range to re-form a gel (pH 4.5 or above). That gel may or may not be quite as thick as it was prior, but your sample isn’t completely ruined either.

Gelmaker Powder is also said to stabilize emulsions. However, I haven’t tested that suggestion yet. The supplier (makingcosmetics.com) also says this version of C10-30 Alkyl Acrylate Crosspolymer was “designed for surfactant-cleansing and electrolyte-containing formulas”. (1)

With it’s ease of use, I can see how this would be a great benefit to a cleansing formula. The recommendation from the supplier is to add Gelmaker Powder into water and mix well until dissolved. Then add surfactants, conditioning ingredients silicones and other ingredients. THEN, adjust the pH to at least 4.5 – 5. More on this in a minute.

I’ve also tested this ingredient with a few shampoo recipes. Let’s just say if you’re going to use this, skip the Polyquaternium-10, which also thickens shampoo formulas. I had a whole goopy shampoo gel with the Polyquat 10! Not quite what I was going for. (. ❛ ᴗ ❛.)

Earlier I mentioned how the supplier recommends adding surfactants and other ingredients to your batch BEFORE adjusting the pH. Well, depending on what surfactants you use, they could cause the pH to rise to where it will activate the gelling properties of Gelmaker Powder. So, you could end up trying to incorporate Surfactants #2 and #3 into a gel if you didn’t premix them all together, first, before adding to the batch.

In other words, it may be best to premix your surfactants together BEFORE adding them to the water+Gelmaker mix. Or, it may be best to add surfactants one at a time so you’ll know which one is causing what effect. In other words, experimentation is key!

Because of this, I also suggest dissolving powdered ingredients into the water+Gelmaker Powder even BEFORE adding surfactants, unless you want to set aside a portion of your water percentage to dissolve your powdered ingredients. But by all means do whatever works best for you.

So, let me be a bit clearer. As of this writing, and based on the recommendations from the Carbopol Ultrez 20 Quick Start Guide, this is my ideal Order of Addition for making a Shampoo with Surfactants:

1. Water (distilled or deionized if you’re selling products)

2. Gelmaker Powder (makingcosmetics.com)

–Let sit until you don’t see any more “white” powder

— Hand stir (no stick blender!) and let sit for 3-5 minutes

3. Add any powdered ingredients (like betaine, panthenol, etc). You may want to skip these though. Remember, this is a shampoo and there’s a high chance some of these ingredients will decrease lather.

4. Add primary surfactants. This will usually be your anionic surfactant(s) (OR nonionic surfactant(s) if you’re making a super gentle, less effective cleanser)

5. Adjust the pH to 4.5-5 or above, if that chosen primary surfactant(s) hasn’t raised the pH for you already.

6. Shampoo batch should be thickener by this time. Add the rest of your surfactants (like coco betaine, hemp-oteric or other amphoteric surfactants)

7. Add your chelator, conditioning ingredients like polyquats, any silicones or salts at this time. (The Carbopol Ultrez 20 literature recommends adding the surfactants to water before adding conditioning ingredients)

8. Add any “pearlizing” ingredients, like Glycol Distearate. This may require heating the batch so add all of your heat-sensitive stuff as necessary to incorporate it well. It may not be at this step but at a step before this one.

9. Add fragrance, color and preservative.

10. Check the pH and adjust it only if necessary. Try to make sure it’s between pH 4.5 and 6.5. Just make sure it’s between 5 and 7 and you’ll usually be fine.

Test it out. One thing about polymers is many will allow you to experiment without the need for heating each batch (if you use water-soluble powders and liquids). It’s always best to try out ingredients with multiple recipes.

If you can, try to implement this ingredient in multiple applications. Try it out in a shampoo. See how it performs in a gel. Try to make a facial serum. That’s the only way you’ll able to tell which applications for which it works best given your needs.

Related

1. makingcosmetics.com – GelMaker Powder

2. CP-34 – Carbopol Ultrez 20 Polymer Quick Start Guide, Page 2 of 2

CURLYTEA

CURLYTEA

Hello, do you think this gel is good for high pH formulations (like about pH 12)? Thank you

According to the supplier, Gelmaker Powder only works between pH 4-9.

Can you use the polymer for water thin emulsion (milky white). If yes, any sample formultaion recipe therof

You probably want to use Sepiplus 400, Gelmaker RHEO or another polymer based emulsifier that offers a milky final product. I haven’t made any milky emulsions I’ve loved so I don’t have any formulas to recommend just yet. At some point in the future I may get to it but not at the moment.